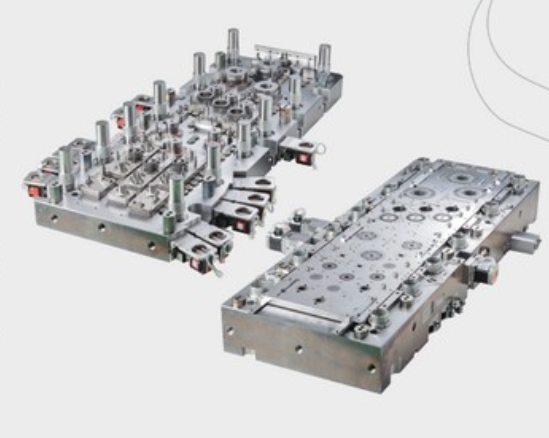

PRECISION TOOLING

PRECISION PARTS

Basic Information

Since its foundation, Mitsui High-tec, Inc. has produced a wide range of tooling (kanagata), specializing in those for motor cores and IC leadframes.

Electric motor cores (rotors and stators), automobile components, coins, IC leadframes, resin injection molding and so on: Mitsui’s stamped products and precision tooling are used all over the world.

Precision tooling for motor core is cost efficient as well as helps environment by conserving energy and natural resources.

Our mission is to provide products useful to people all over the world.

In fact you will find Mitsui motors in various products such as air conditioning systems compressor, hybrid vehicle drive motors.

We also newly built a precision tooling factory as an effort for improving product quality under clean, controlled environment.

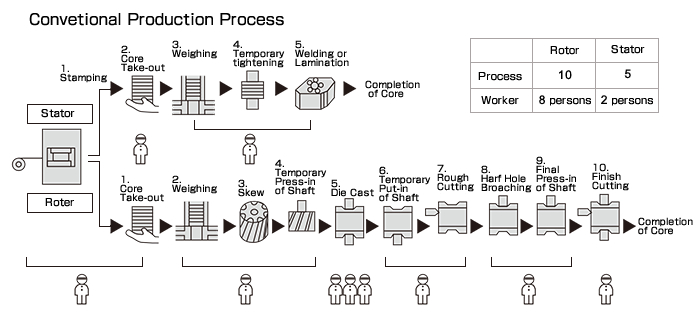

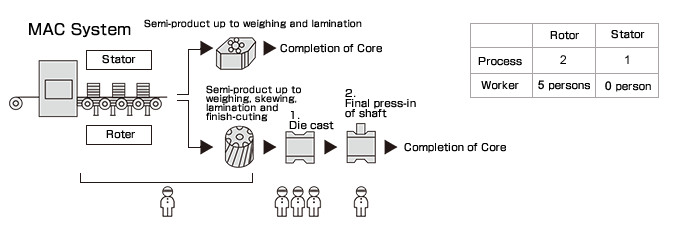

MAC SYSTEM "MITSUI AUTOMATIC CORE ASSEMBLY SYSTEM"

The MAC system is an epoch-making one, which can provide an integrated process from punching to weighing, stacking, and lamination. By this system, rotors and stators can be made into a complete product through only two processes of stamping and lamination, allowing full automation of the motor core manufacturing process.