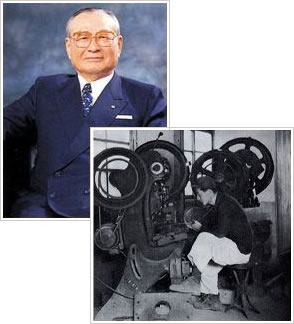

Company History

Founder, Yoshiaki Mitsui, Introduction

Born in Kumamoto Prefecture in 1921.

Passed away- July 10th, 2008.

Founder of MITSUI MFG. CO., LTD. currently Mitsui High-tec,Inc.

Continuously absorbed in the development of stamping tools and responsible for driving the transition from hand-finished technology to post-heat treatment and full-grinding finishing.

Recipient of the Japanese Emperor’s Indigo Ribbon in 1984.

Time and time again, the leadership of Mitsui’s tenaciously challenging spirit achieved industry paradigm shifts for technology of high precision tungsten carbide tools, IC leadframe stamping tools, MAC system (Mitsui Automatic Core assembly system), and spot electroplating production equipment. Also, aggressive erection of factories overseas contributed to early successes. In the short span of a single generation, Mitsui High-tec has become a truly global leading-edge technology corporation.

“Roads open up for those who travel a noble path” is the ideology. Not swayed by fashions of the time, employees are constantly asked, “What is the truth?” This simple spirit embodied by the Corporate Motto guides the corporation.

HISTORY

- January,1949

- Yoshiaki Mitsui Founded Mitsui High-tec

Started Manufacturing and sales of dies Company was Located at Tsutsuimachi 1-Chome,Yahata City, Fukuoka Prefecture(present Kurosaki 5-chome, Yahatanishi-ku, Kitakyushu City).

- January,1950

- Succesfully Manufactured it’s first surface grinder.

- March,1954

- Shipped the first Die manufactured with full grinding after heat treatment.

- April,1957

- Mitsui Manufacturing was founded with a Capital of 1.5 million yen.

- December,1958

- Developed tungsten carbide die (Notching type).

- October,1960

- Constructed Komine plant(present Head Quarter).

- April,1961

- Established mass production and sales of surface grinders.

- May,1966

- Developed tungsten carbide die for stamping IC leadframe.

- August,1966

- Opened Office in Chigago Illinois, USA.

- June,1969

- Started mass production and sales of IC stamped leadframes using tungsten carbide progressive die technology.

- August,1974

- Developed ultra-high speed dies (1450 spm).

- August,1974

- Developed MAC (Mitsui Automatic Core) assembly system laminated-core binding system.

- October,1979

- Started IC Leadframe plating business and developed automatic continuous spot plating machine.

- May,1984

- Changed Company name to Mitsui High-tec, Inc.

- July,1984

- Started IC assembly business.

- September,1984

- Mitsui High-tec, Inc. was listed on the Fukuoka Stock Exchange.

- April,1985

- Started Mass-production of photo etching IC leadframes.

- September1985

- Mitsui High-tec, Inc. was listed on the Second Section of Tokyo Stock Exchange.

- April,1987

- Started Tooling parts sale.

- July,1991

- Mitsui High-tec, Inc. was listed on the First Section of Tokyo Stock Exchange.

- April,1997

- Developed die technology to manufacture motor core for Hybrid car.

- March,1999

- Five domestic plants certificated ISO14001.

- July,2000

- Developed die technology to manufacture ultra small core with diameter of 2.7mm using MAC system.

- December,2000

- Developed die technology to manufacture ultra thin core of 0.15mm thickness using MAC system.

- September,2001

- Constructed first phase of new state of the art tool and die plant in Nobu, Yahatanishi-ku, Kitakyushu City.

- February,2003

- Founded Mitsui Stamping Co.,Ltd. in Aza Nishikukioka, Oaza Maeda,Yahatahigashi-ku,Kitakyushu City.

- January,2006

- Commenced mass production of マグネットモールド™(Magnet Mold™) (laminated motor cores with embedded magnets have been adopted by the automobile industry and are included in hybrid vehicles)

- November,2007

- Recognized by Moji Customs as an authorized exporter with an outstanding trade compliance record (the first company headquartered in Kyushu to receive this recognition)

- January,2009

- Commemorated the sixtieth anniversary of Mitsui High-tec, Inc’s founding

|